Improve Efficiency of a Water Power Plant and Help to Grow Green Energy

This story tells us how the efficiency of an existing water power plant increased up to 10%, using modern strain-gauge technology and the PMX measuring system. The Iron Gate I (Djerdap Gorge) Hydroelectric Power Station is the largest dam on the Danube River, and one of the largest hydro power plants in Europe. It is located on the Iron Gate gorge, between Romania and Serbia.

The project started in 1964 as a joint-venture between the governments of Romania and Yugoslavia for the construction of a major dam on the Danube River, which would serve both countries. At the time of completion in 1972, it was one of the largest hydroelectric power stations in the world with twelve units generating 2,052 MW, divided equally between the two countries at 1,026 MW each.

Previous mechanization solutions reach their limits

After being in operation for more than 30 years, the revitalization project of six turbines started in Serbia in 2009. The aim was to increase the installed power as well as the efficiency by 10%. The installed turbines on Đerdap1 are old Kaplan turbines with adjustable blades, and the old design needed change and optimization. The target was to determine, through extensive tests of operational states, where the ratio of produced electricity and consumed water was the largest. For this purpose, IEENT (The Institute of Nikola Tesla in Belgrade) in cooperation with MFB (The Faculty of Mechanical Sciences, University of Belgrade) and TRC PRO (Technical Research Center) designed a concept of how to measure the efficiency in real-time under working conditions. To gain the highest effort and increase, the power production of the turbine and the mechanical design of the turbine blades were calculated and designed according to the latest standards.

Reliable sensor technology

The basic tool for the measurement are strain gauges, which are installed directly at the turbine wheel input stage. Strain gauges have the advantage of offering a high long-term stability. This is important in this project because they operate in a virtually endless operation in the plant and it is not efficient to stop the turbine for a recalibration.

- The first strain gauge measurement performed the torque measurement.

- The second strain gauge measurement performed the axial force and speed measurements on the turbine in the input stage.

Strain gauges for torque and axial force measurement were positioned on the shaft between turbine wheel and generator (above the turbine wheel and below the generator). They were placed on four axes (view from above: four points equally spaced on the circumference).

For the torque measurement, the engineers decided using the strain gauge type HBM XY41-3/700. Two strain gauge full bridges are working in parallel connection.

For the axial force measurement, the engineers chose the strain gauge type XY31-3/350. Four strain gauge full bridges are working here in parallel connection.

The measurement and control system needs to fulfill several tasks, such as fast and reliable measurements, easy set-up, real-time calculations, diagnosis information, no additional software installation, and efficient pricing. These can be archieved with the PMX measurement and control system.

In the first step, PMX was used as a four-channel amplifier for voltage inputs. The first input was the voltage from the telemetry system for torque measurements using the strain gauges installed on the turbine. The second input was the telemetry system for axial force measurement in the turbine, and the third input was rotational speed. All signals were sampled with 19.2 kHz, which guarantees a high measurement-bandwidth and evaluation of the measurement signals.

All adjustments to the PMX system are handled via the standard Ethernet-interface and the internal PMX web server. This solution offers the benefit of adjustments being done via the machine network or even remotely if the additional Wi-Fi is available. So each engineer had a real-time view of the application and the status of the test. An integrated operator control prevented insecure operation.

Powerful real-time calculation with the PMX “Smart Functions”

In the second step, the desired and relevant information had to be calculated in real time. This can be done with the Smart Functions of PMX, which can be used by the operator very easily without having extensive software skills. They offer several mathematical functions, like a pocket calculator, logical functions, and process evaluations up to controller functions like PID-controller.

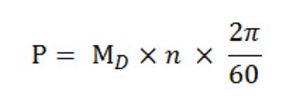

To calculate the mechanical power, the following formula can be used:

Units: P: W; M: Nm; n: rpm.

Safe installation and diagnosis

As an additional protection against dust and EMI, the PMX amplifier was mounted in a cabinet, which includes the supply of the telemetry system also.

The glass in the cabinet allows a direct view onto the PMX and the diagnostic LED indication. This is an easy and quick indication to determine a potential error on the device and the measurement status. This is a big advantage for the service engineers, as they can get quick information without using any additional test equipment.

A detailed and deeper diagnostic is stored in the PMX Log-file. This file is stored in the internal memory of the PMX. It covers all upcoming errors of the device and measurement, as well as any changes to the parametrization made by the operators. This allows 100% coverage of the whole test and measurement process.

“A very helpful tool for parameterization, setup and control we found the PMX web server. We didn’t need any additional software and could use the standard web browser on our PC’s tablet or smartphone. And it is permanently available in real-time over the whole power-plant area”, says Hotimir Licen from TRC PRO.

Process data-acquisition and evaluation

In the requirements, the engineer-team defined an easy-to-use, robust, and powerful DAQ and evaluation software, which has to capture all measurement signals at full speed as well as the calculated channels from the PMX system. These channels are calculated in real time, which means they are calculated with the same speed as the measurement signals. Additionally, the software has to visualize and store all the data and generate a printed report on demand.

All data was captured with HBM’s catman data acquisition software:

After finishing the project on A4, efficiency tests were performed and new turbine characteristics were determined.

Here are once again the highlights of the implemented HBM measurement solution:

- Fast and easy deployment

- Easy setup and helpful diagnosis

- High resolution, accuracy, and speed

- Calculated channels inside the device:

- Dynamic signals and filtered signals

- Torque calculation from strain measurements

- Force calculation from strain measurements

- Power calculation from torque and rotational speed measurement

- Web visualization application development for data storage without a PC and visualization on a PC, tablet, or smartphone (any device with the web browser).